- MAGMASOFT CASTING SIMULATION SOFTWARE

- MAGMASOFT CASTING SIMULATION CODE

- MAGMASOFT CASTING SIMULATION DOWNLOAD

- MAGMASOFT CASTING SIMULATION WINDOWS

MAGMASOFT CASTING SIMULATION SOFTWARE

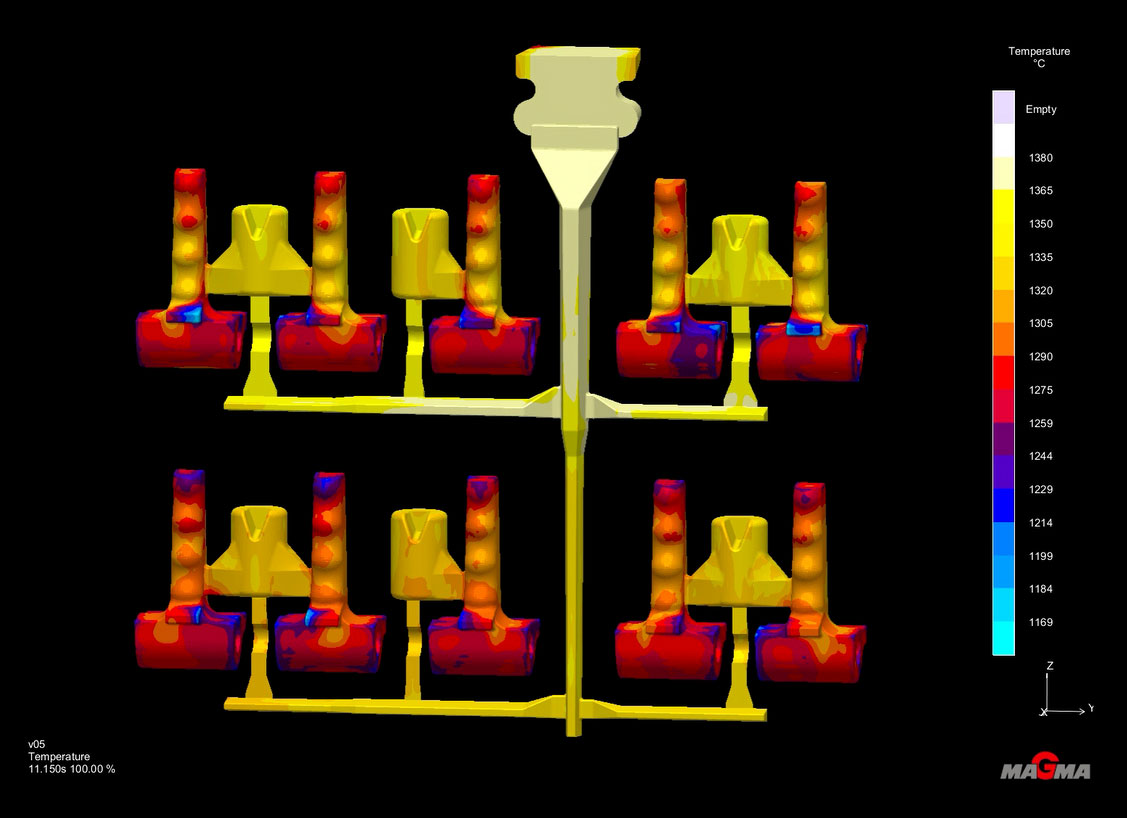

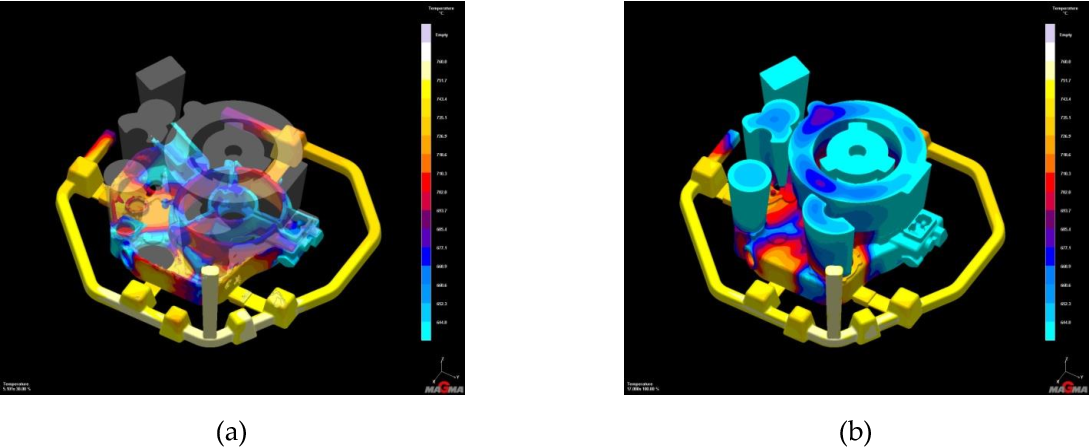

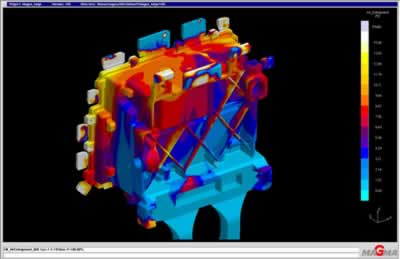

The software supports the user in the modeling of the component, the determination of melting practice and casting methoding through to model and mold making, heat treatment, and finishing. The range of application of MAGMA solutions comprises all cast alloys, from cast iron to aluminum sand casting, permanent mold and die casting up to large steel castings. MAGMA5 consists of a base module and a set of additional modules that cover all steps of the casting production. MAGMAs product and service portfolio includes simulation software MAGMASOFT, with. This not only results in a reduction in pre-production sampling as the precise layout of the complete casting system leads to energy, material, and tooling savings. The company was founded in 1988 and has its headquarters in Aachen, Germany. Simulation accurately describes a cast component's quality up-front before production starts and the casting methoding can be designed with respect to the required component properties. The software stands for the prediction of the entire casting component quality and process chain by providing a better understanding of mold filling, solidification and cooling and allows the quantitative prediction of mechanical properties, thermal stresses and distortions of the resulting castings. MAGMA5 is the standard solution for the simulation of casting processes.

( October 2015) ( Learn how and when to remove this template message) Please help improve it by removing promotional content and inappropriate external links, and by adding encyclopedic content written from a neutral point of view. For further information how we process your personal data, please follow this link Privacy Policy.This section contains content that is written like an advertisement. Simulating the casting process with MAGMA5 provides foundries with. It will not be passed on to third parties. MAGMA is the next generation of simulation software for virtual experimentation and.

MAGMASOFT CASTING SIMULATION DOWNLOAD

When downloading the PDF, please leave your contact data (you will receive the download link by e-mail) and thus agree to the processing and storage of it by MAGMA casting technology GmbH in Aachen.

MAGMASOFT CASTING SIMULATION WINDOWS

In particular, it will discuss the benefits of Autonomous Engineering to the investment casting process, a new methodology for systematically investigating process windows by means of virtual Design of Experiments or autonomous optimization. Furthermore, you will understand how casting process simulation accompanies and optimizes the production process. This seminar conveys all the important parameters influencing the properties of ferrous alloys as a casting and construction material. Using real industrial applications as examples, this paper will provide an overview of new developments and demonstrate current capabilities of the simulation software Magmasoft in addressing the entire process chain of investment casting virtually. Simulation of Cast Iron Basics, Metallurgy, Casting Defects. It allows engineers to assess the technical feasibility of new components and to find the best compromise between casting quality and the production costs before creating costly physical prototypes.

Process simulation is the state-of-the-art tool for eliminating casting trials and improving casting quality, which significantly reduces production costs and time. Nonetheless, the manufacturing costs and lead-times during production can quickly limit the competitiveness of investment casting as the preferred manufacturing route. 2.1 Simulation of Casting Processes For the simulation of casting.

MAGMASOFT CASTING SIMULATION CODE

Investment casting has benefited many industries as an economical route to cast near-net-shape metal parts with high geometric complexity and dimensional accuracy. This three - dimensional effect is only detected by the 3D simulation code MAGMASOFT.

0 kommentar(er)

0 kommentar(er)